Multi-Port Fuel Injection

Most modern vehicles have multi-port fuel injection (MFI) with a separate fuel injector for each cylinder. This system mixes the fuel and air together right in the intake port for eachengine cylinder just ahead of the intake valve.

Here's how multi-port fuel injection systems work:

1. An electrical fuel pump pumps fuel from the fuel tank through a fuel filter to the fuel rail assembly, which carries fuel under pressure to the fuel injectors (see Figure 7-6).

The fuel rail assembly also may contain the fuel pressure regulator, which maintains proper fuel pressure and meters unused fuel back to the fuel tank. Fuel injectors, one for each cylinder, are attached at one end to the fuel rail and at the other end to the intake port in the engine.

2. A whole bunch of sophisticated sensors measure a variety of factors and send messages to the ECU, which decides how much fuel to inject at any given time.

These sensors are so perceptive that they even check the weather; how much weight you're carrying in the vehicle; and whether you're starting up, speeding up, slowing down, or idling at a light. This information makes the system respond faster and results in greater fuel economy than older vehicles achieved with throttle-body fuel injection.

3. The ECU completes the electrical circuit to the injector solenoid for the proper injector pulse width, and fuel under pressure is injected into the intake port just before the intake valve.

Sequential Fuel Injection

More recent fuel-injected engines feature sequential fuel injection (SFI) in which the fuel injectors fire in sequence rather than all at once. Because each injector opens individually just before its intake valve opens, the fuel isalways sprayed right into an open port and therefore stays in suspension.

This type of system is more efficient than a system whose injectors fire simultaneously. (For example, if you have a six-cylinder multi-port fuel-injected engine that’s simultaneously fired, three of the six injectors are pulsed together, and then the other three injectors are pulsed.) In addition, emission levels are lower in an SFI system, but the system requires a separate electricalcircuit for each injector.

Gasoline Direct Injection

The gasoline direct injection (GDI) system is relatively new in the United States but is expected to grow more popular as time goes on. It resembles diesel technology but uses gasoline instead of diesel fuel. Instead of being mixed with air to form a fuel/air mixture prior to injection, the gasoline is injected directly into each engine cylinder. The b uses data from various sensors to time the injection of the fuel into the cylinder and regulate the resultingfuel/air mixture for maximum efficiency under varying driving conditions.

Although a gasoline direct injection system is currently more expensive to build than a standard engine, it measures fuel so precisely that you get the most bang for the buck. However, to handle its higher emission of NOx emissions (nitrogen oxides), the GDI system requires a more costly catalytic converter than a standard engine does. Because of the greater fuel efficiency, automakers are currently working on gasoline direct injection systems to reduce their emissions and bring down the cost. As fuel becomes more expensive and the efficiency of these engines increases relative to the costs,they’ll become more popular and more widely available.

|

Improvements to Fuel Injection Systems Two exciting ways that fuel injection systems are being perfected is the replacement of moving parts with stationary ones and solid parts with intangible substances. By reducing the number of mechanical parts, car manufacturers hope to reduce production costs and create devices that are less susceptible to breakdown due to physical stress. Now, I’ve been in favor of simplification ever since my mother taught me to always buy the washing machine with the fewest gadgets on the principle that the fewer parts involved, the fewer things there are that can break down. But I keep having this fantasy that if they continue to replace mechanical car parts with miniaturized and computerized equipment, eventually I may lift the hood of my vehicle and find nothing but a little black box! At that point, when things go wrong, I’ll probably have to seek the services of a wizard rather than a technician! The upside is that using less metal, plastic, and rubber places less strain on the world’s dwindling supply of raw materials. It also reduces the amount of energy consumed by production (as well as driving) and the number of disposal facilities required to process all the worn and broken stuff that gets thrown away. So let’s hope that the trend continues, wizards and all. |

Throttle-Body Fuel Injection

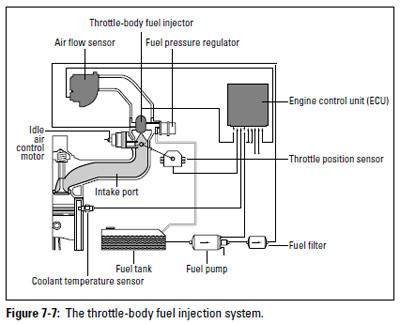

Throttle-body fuel injection (TBI) was the first fuel injection system to become popular as carburetors were being phased out. This system is less complicated than the multi-port fuel injection systems found on more recent vehicles, but it’s also less efficient. Instead of using individual fuel injectors to pump the fuel into each cylinder, the TBI system mixes the fuel and air together right in the throttle assembly of the vehicle. Along the way, sensors monitor air flow, throttle position, temperature, and other factors and report back to the ECU (engine control unit). You can see the parts of this system in Figure 7-7. Some of these systems use solenoids to spray the fuel into the airstream in the throttle through a fuelinjector nozzle.

If you have a vehicle with throttle-body fuel injection, here’s how it works:

1. An electrical fuel pump pumps fuel to the throttle body assembly. The throttle body assembly looks similar to a carburetor and houses the fuelinjector(s) and a fuel pressure regulator.

2. The fuel pressure regulator maintains proper fuel pressure and metersunused fuel back to the fuel tank.

3. A computer controls one or two fuel injectors mounted in the throttle body assembly. The computer applies electrical current to the injector solenoid for the proper duration (called the injector pulse width), and fuel under pressure is then injected and mixed with air as it passes through the throttle on its way to the engine.

From Auto Repair for Dummies, copyright © 2009 by Wiley Publishing, Inc., Indianapolis, Indiana. Used by arrangement with John Wiley & Sons, Inc.